In a world where online consumers expect faster delivery and seamless post-purchase experiences, fulfillment services have become a cornerstone of successful e-commerce operations. Fulfillment is no longer just a backend task—it is a strategic function that directly impacts customer satisfaction, operational efficiency, and business scalability.

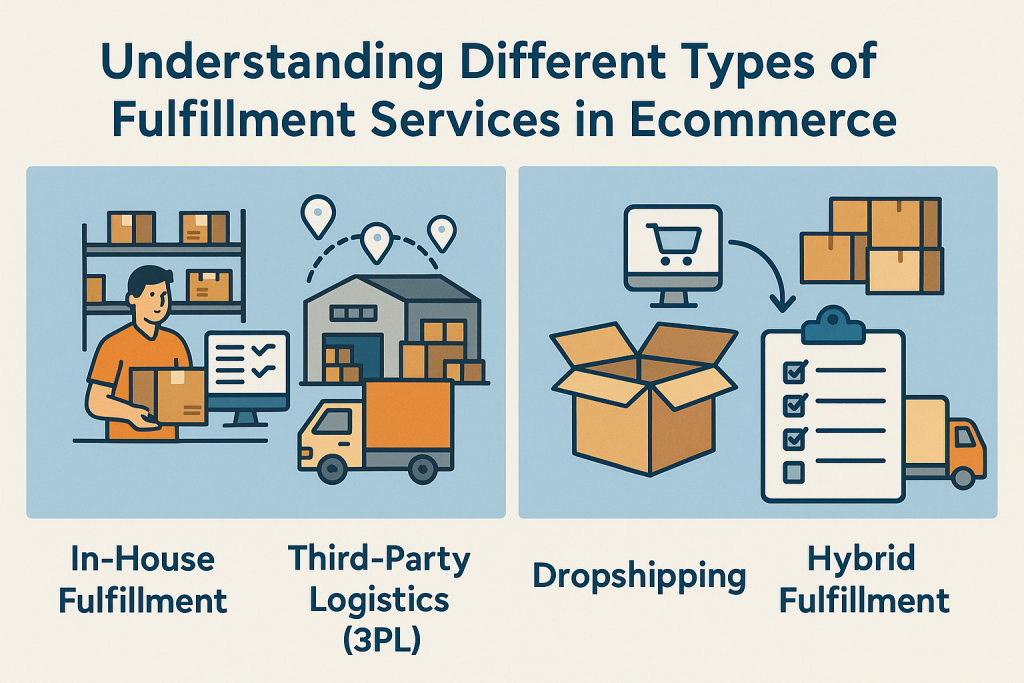

Companies today must evaluate and choose between various fulfillment models, including in-house fulfillment, third-party logistics (3PL), dropshipping, and hybrid models. Each has unique strengths, limitations, and use cases depending on the stage and structure of the business.

What Is Fulfillment and Why It Matters

At its core, order fulfillment involves storing products, picking and packing items once an order is received, and ensuring they are shipped and delivered accurately and on time. While simple in theory, the complexity grows with order volume, product diversity, geographic coverage, and customer expectations.

A streamlined fulfillment process reduces lead times, lowers shipping errors, improves return management, and ultimately enhances the customer experience. In a competitive market, fulfillment can be a key differentiator for online brands.

In-House Fulfillment: Full Control, Higher Responsibility

In-house fulfillment refers to managing the entire order process internally—handling your own storage, staffing, picking, packing, and shipping. This model offers maximum control over inventory and customer experience.

It’s well-suited for businesses that prioritize branding and want to oversee every touchpoint, from custom packaging to return handling. However, it requires significant investment in warehouse space, staff training, logistics software, and shipping negotiations. As order volumes grow, in-house operations may struggle with scalability and efficiency.

Third-Party Logistics (3PL): Outsourcing for Scale

Partnering with a 3PL provider allows businesses to outsource their fulfillment processes to specialists who handle storage, processing, and shipping across multiple regions. It’s a highly scalable solution, particularly attractive for brands looking to expand without investing in infrastructure.

3PLs also provide access to distributed warehouse networks, negotiated shipping rates, and advanced logistics technology. However, outsourcing means less control over packaging customization, handling procedures, and in some cases, customer service—making partner selection crucial.

Dropshipping: Low-Risk, Limited Control

Dropshipping is a fulfillment model where businesses sell products they don’t physically stock. Instead, suppliers ship products directly to the customer after an order is placed.

This model minimizes upfront costs and inventory risks, making it ideal for new e-commerce businesses or stores testing product-market fit. However, dropshipping limits quality control, shipping speed, and transparency. Brands relying heavily on dropshipping often face customer service issues due to inconsistent supplier performance.

Hybrid Fulfillment: The Best of Both Worlds

Many modern e-commerce brands use a hybrid fulfillment strategy, blending internal and external resources. For example, a business may handle high-margin or branded products in-house while outsourcing bulk or international shipments to a 3PL.

Hybrid models offer flexibility, cost optimization, and resilience against supply chain disruptions. They are particularly effective for businesses operating across multiple channels (DTC, B2B, marketplaces) or with seasonal fluctuations in order volume.

Key Factors When Choosing a Fulfillment Strategy

There is no one-size-fits-all model. Your ideal fulfillment strategy should reflect:

- Order volume and growth trajectory

- Product type and SKU complexity

- Geographic reach and delivery timeframes

- Customer expectations for packaging and service

- Internal resources and logistics know-how

Early-stage brands may start with in-house or dropshipping to retain agility, while scaling brands benefit from 3PL or hybrid models for regional expansion and cost efficiency.

Future Trends: Automation, Sustainability, and Intelligence

The future of fulfillment is driven by three major trends:

- Automation – Robotics, AI-powered picking systems, and predictive inventory tools are optimizing warehouse efficiency and reducing human error.

- Sustainability – Consumers increasingly expect eco-conscious practices, prompting brands to adopt recyclable packaging, carbon offset shipping, and green warehousing.

- Data-Driven Optimization – Fulfillment analytics platforms now enable real-time order tracking, supply chain visibility, and performance forecasting across all channels.